- Case Studies >

- The Elios 3 UT Payload: avoiding 15,000 hours of work at...

The Elios 3 UT Payload: Avoiding 15,000 Hours Of Work At Height For Hull Inspections

Benefits In A Nutshell

|

Safety |

Speed The Elios 3 can be deployed within 30 minutes of arrival on site, and help cut thousands of hours of work spent on scaffolding. |

|

Localization The results from the UT drone survey with the Elios 3 can be viewed within a 3D model, making it easy to identify and return to points of interest for further analysis or maintenance work.

|

Reporting C-Bird completed the UTM and close-up survey required for the ship’s periodical 5-year survey and their data was certified by a class society. |

All shipping vessels must have a special periodical inspection every 5 years, with smaller inspections required at shorter intervals too. The older a ship is, the more frequent and intensive the inspections become - with some form of major inspection taking place every 30 months after a ship is over 15 years old. These inspections are critical to the ship being certified as safe to operate and can be very costly, with ships waiting in dry dock for work to be completed. As part of this process, the ship’s hull must be inspected with ultrasonic thickness (UT) measurements to ensure it is structurally sound, as well as visual inspections of target areas. This is focused on the midship area which is under the most pressure when the ship is at sea. These inspections are vital for identifying faults that may not be visible to the human eye or hidden within the ship’s structure. A combination of ultrasonic thickness measurements (UTM) and visual surveys ensures the inspectors can be confident in their results and that the ship inspection is completed according to industry standards.

UT Inspections On Ships In The Past

The process for accessing UT inspection points and taking measurements typically requires many hours of work. Crews as big as 30 people enter the space and erect scaffolding before a UT inspector can climb the structure and take UT measurements. The scaffolding has an inherent risk for inspectors due to working high up and poses an additional danger to the ship; if a piece is accidentally left behind, it can get sucked into the tank’s pump and break it, which would require the ship to be drydocked for repairs.

The inspection process for Cargo tanks within the ship usually take several days and require special permits for the work at height or in confined spaces. In addition, the ship must be in drydock during the inspection. As drydock is charged by the day, the associated costs with a slower inspection method are much higher. Faster inspection methods, such as with the Elios 3 UT drone, present an attractive alternative while still gathering critical data.

The estimated cost of building the scaffolding required for surveying a 15 year old tanker can be $300,000 - $700,000 alone. The ship can be out of commission from anywhere between 40 to 60 days, with the dry dock costs reaching between $4-6 million - including further inspection and/or maintenance work. Using a drone to cut the need for scaffolding thus not only makes work safer but can drastically reduce costs too.

Image right: Scaffolding can take thousands of hours and require teams of over 30 people to erect. This work is on a huge scale including potential risks from work at height.

C-Bird, a specialized ship inspection company, frequently uses the Elios 3 for UT inspections for vessels that are over 15 years old. The C-Bird inspectors know that the Elios 3 is faster than traditional methods while gathering the UT and visual data required for a ship survey. This would improve safety standards and also help reduce the time and money spent on scaffolding management and speed up the overall process.

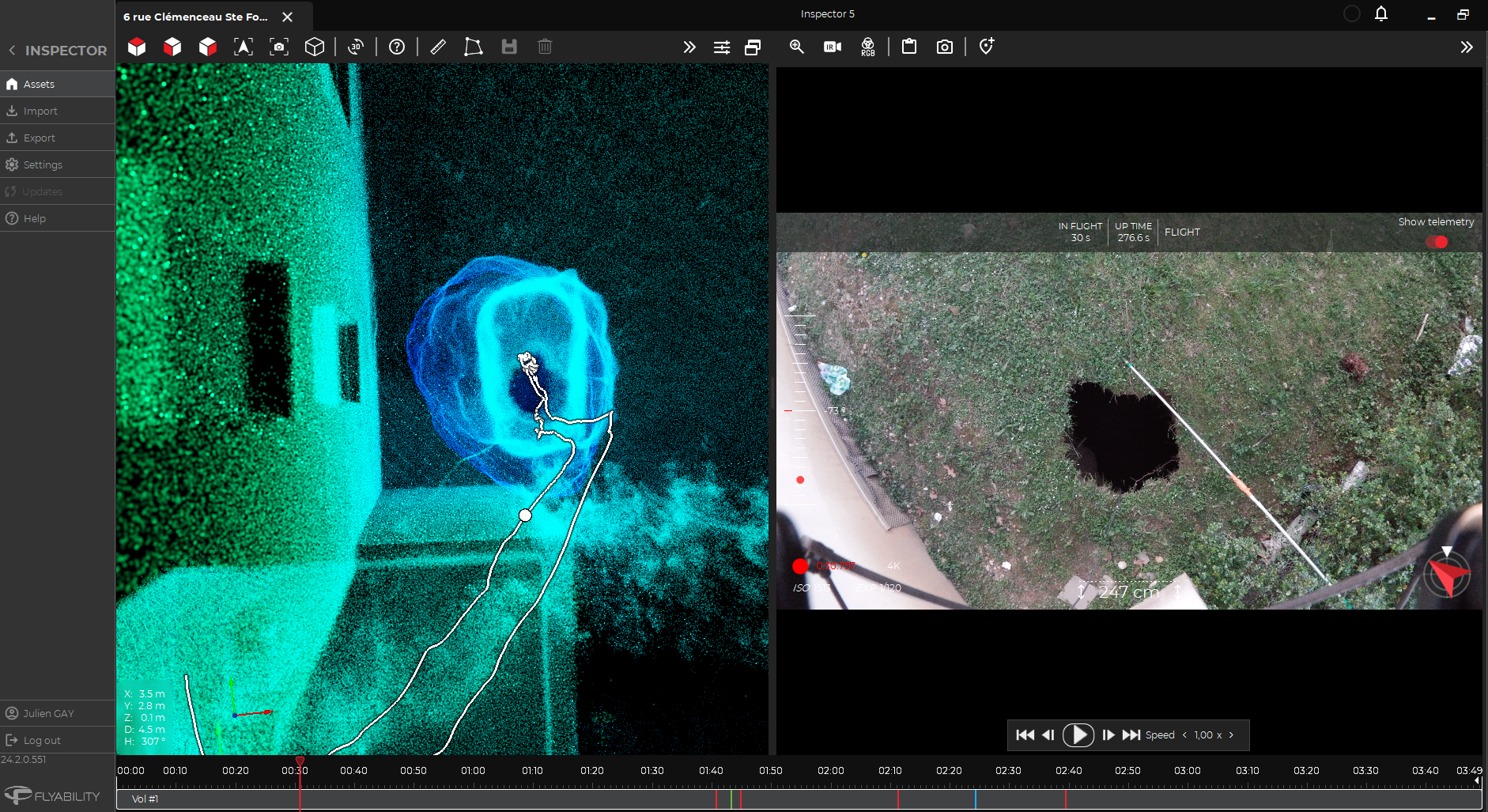

A UT inspection can require entering confined spaces inside a ship ballast tank

How UT Drone Inspections Serve The Maritime Industry

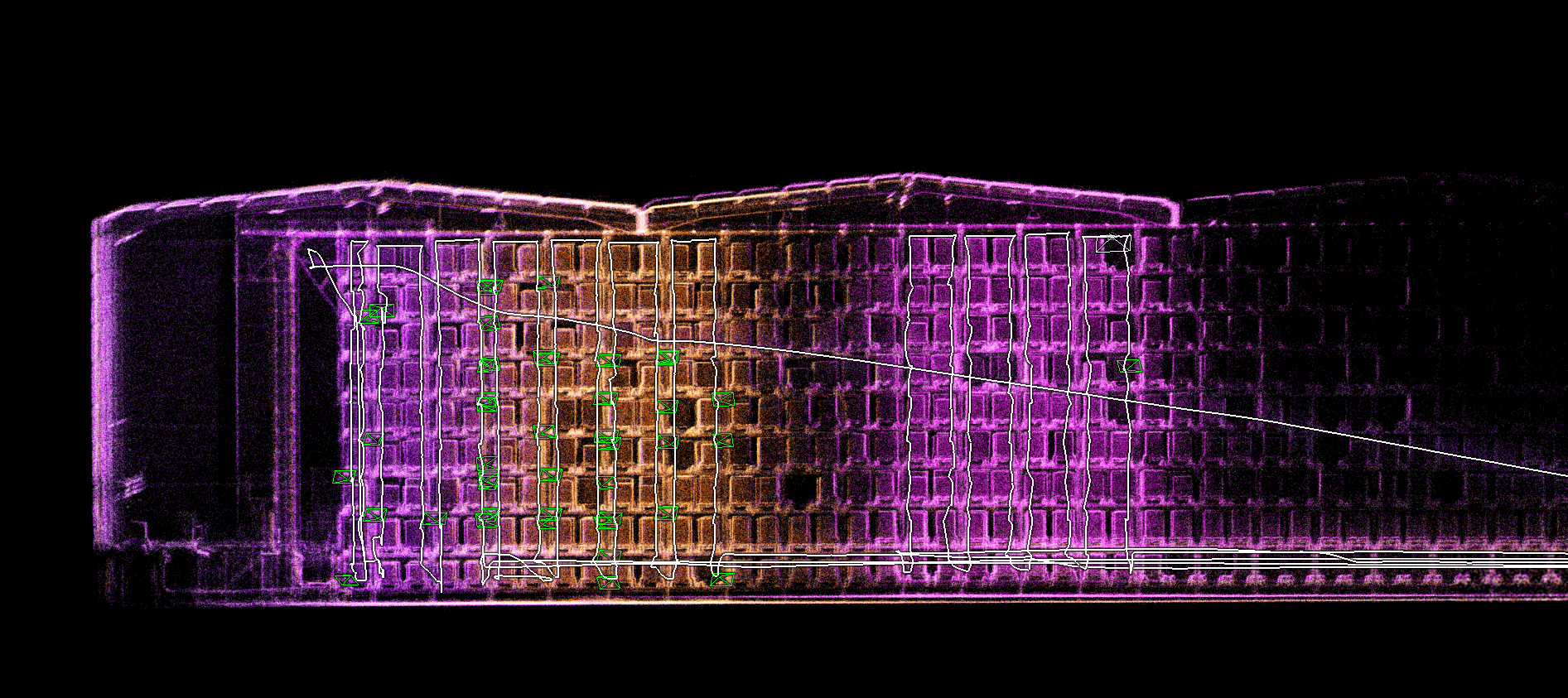

C-Bird was contracted to inspect 12 oil tanks in a medium-sized ship. Malcolm Connolly, the C-Bird CEO, was asked to conduct gauging measurements and close-up inspections for the oil tanks inside the ship as part of its periodic survey. The ship’s tanks measured 38 x 28 x 20 meters, laid out with 6 transverse web frames in each of the cargo oil tanks (COT) and then transverse bulkheads between each COT.

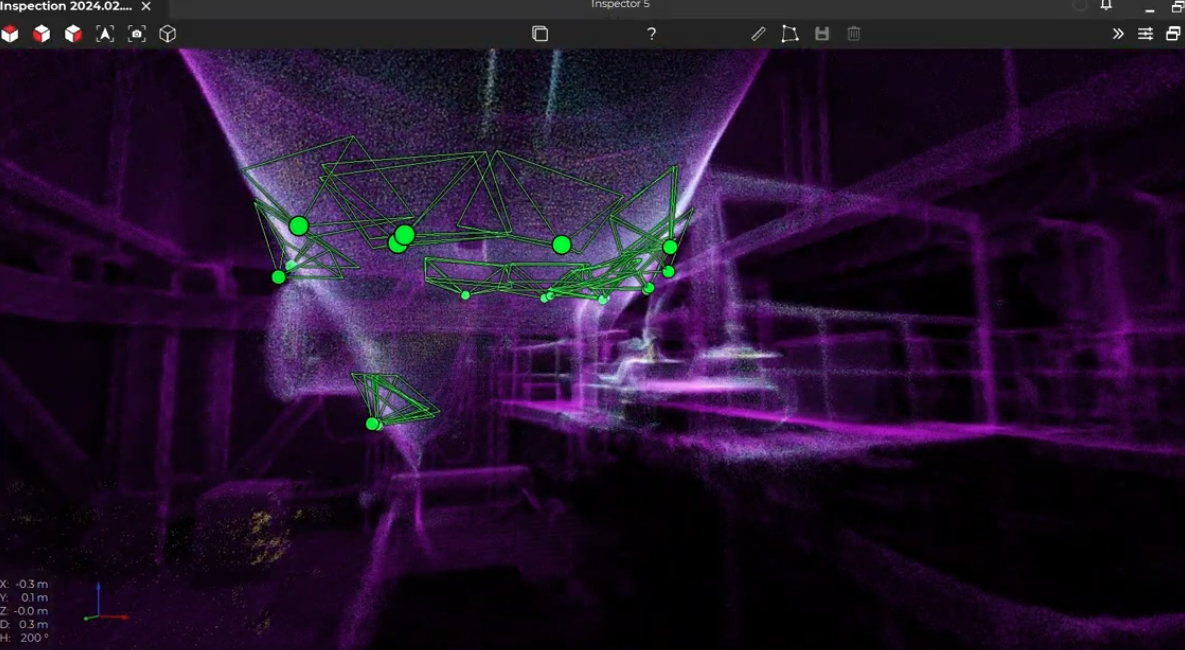

For this project, Malcolm and the C-Bird team turned to the Elios 3 and its new UT payload. The drone is capable of detailed LiDAR mapping and visual inspections. The visual element is vital to periodical surveys as any visual records must be captured at arm’s length from the object being inspected. The drone can quickly gather this visual data at the required distance without an inspector having to climb scaffolding or work in confined spaces. As one of the Flyability product advisors and beta-testers for the new UT payload, Malcolm saw this as the perfect opportunity to test how the drone and its UT probe would work in a typical NDT environment alongside completing the ship’s visual inspection.

Performing A Ship UT Inspection With The Elios 3

Instead of relying on traditional labor-intensive methods, C-Bird used the UT probe with their 2 Elios drones to complete the inspection of the 12 oil tanks. They completed the inspections with the guidance of a class inspector who provided information about what needed to be tested. This drone-based inspection method was much faster than the typical scaffolding approach; once the equipment is onboard the ship, the UT inspection can begin immediately - a huge saving compared to the thousands of hours associated with scaffolding. C-Bird flew the Elios 3 UT drone around each tank and took measurements in several locations as required by the inspection plan and any additional areas that the class surveyor requested. The UT inspections and visual inspections were both completed within 7 days. At the end of the flights, the pilots cross-checked with the class inspector that the Elios 3’s spot measurements matched the required number and location of measurement points.

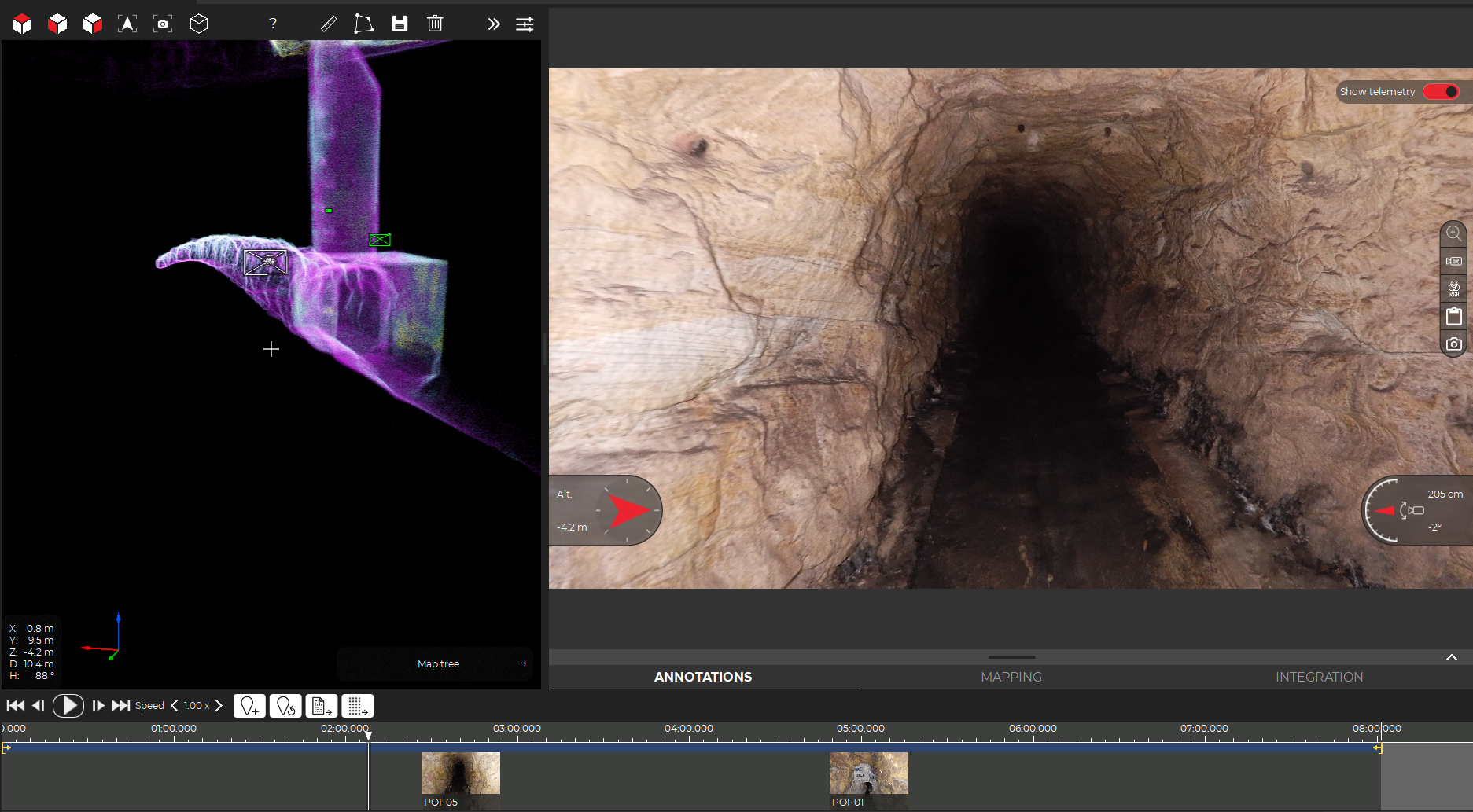

A photo from the close visual inspection with the Elios 3 inside the COTS.

The Elios 3 streamlined the visual inspections necessary for this process. The drone enabled the pilots to gather both visual and UT data during the flights, providing a close-up view of the areas being surveyed at the required distance. This made it possible for C-Bird to get the information they needed twice as fast by having one drone focused on visual inspections and the other measuring UT points. This provided results that included a clear visual display of the points of interest and UT spot measurements.

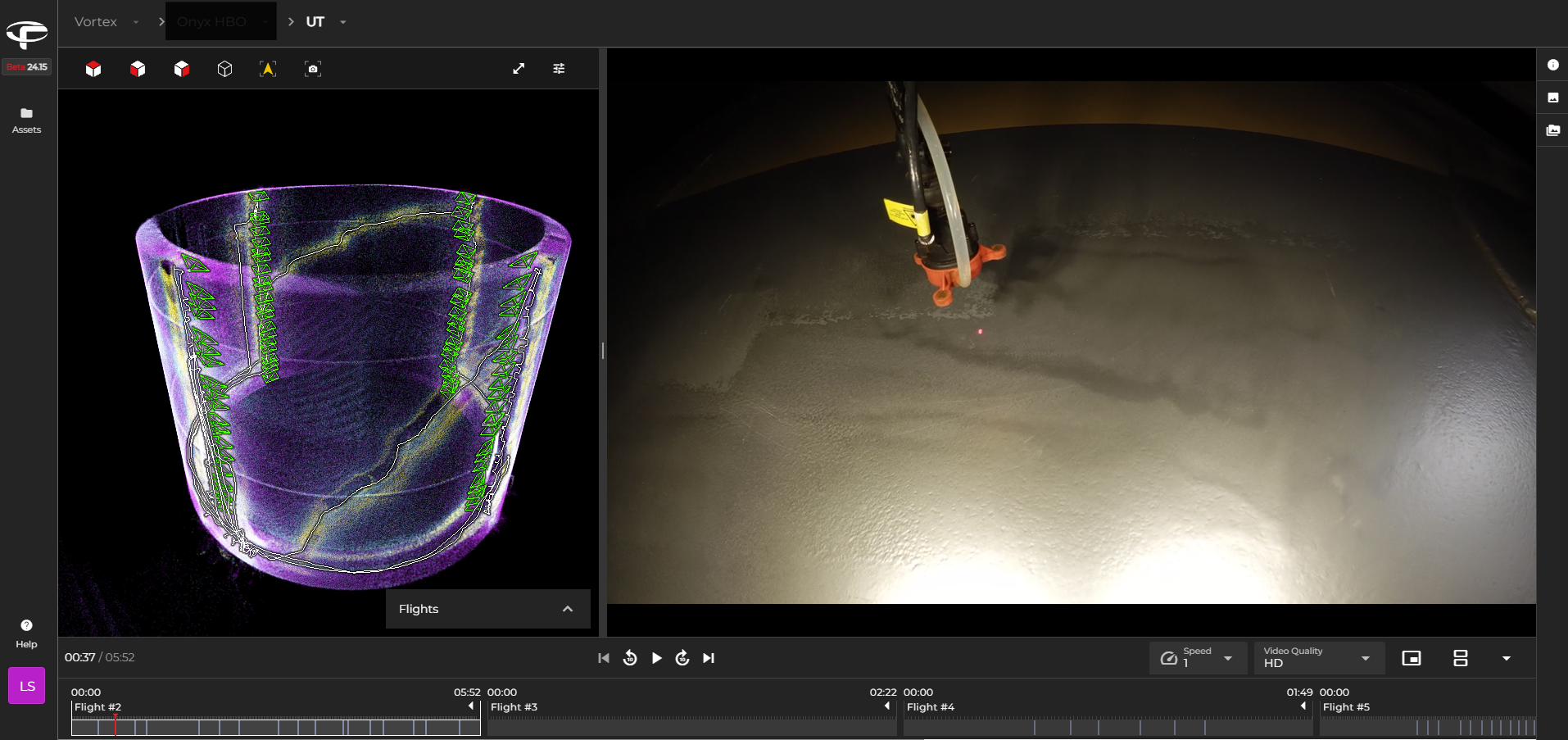

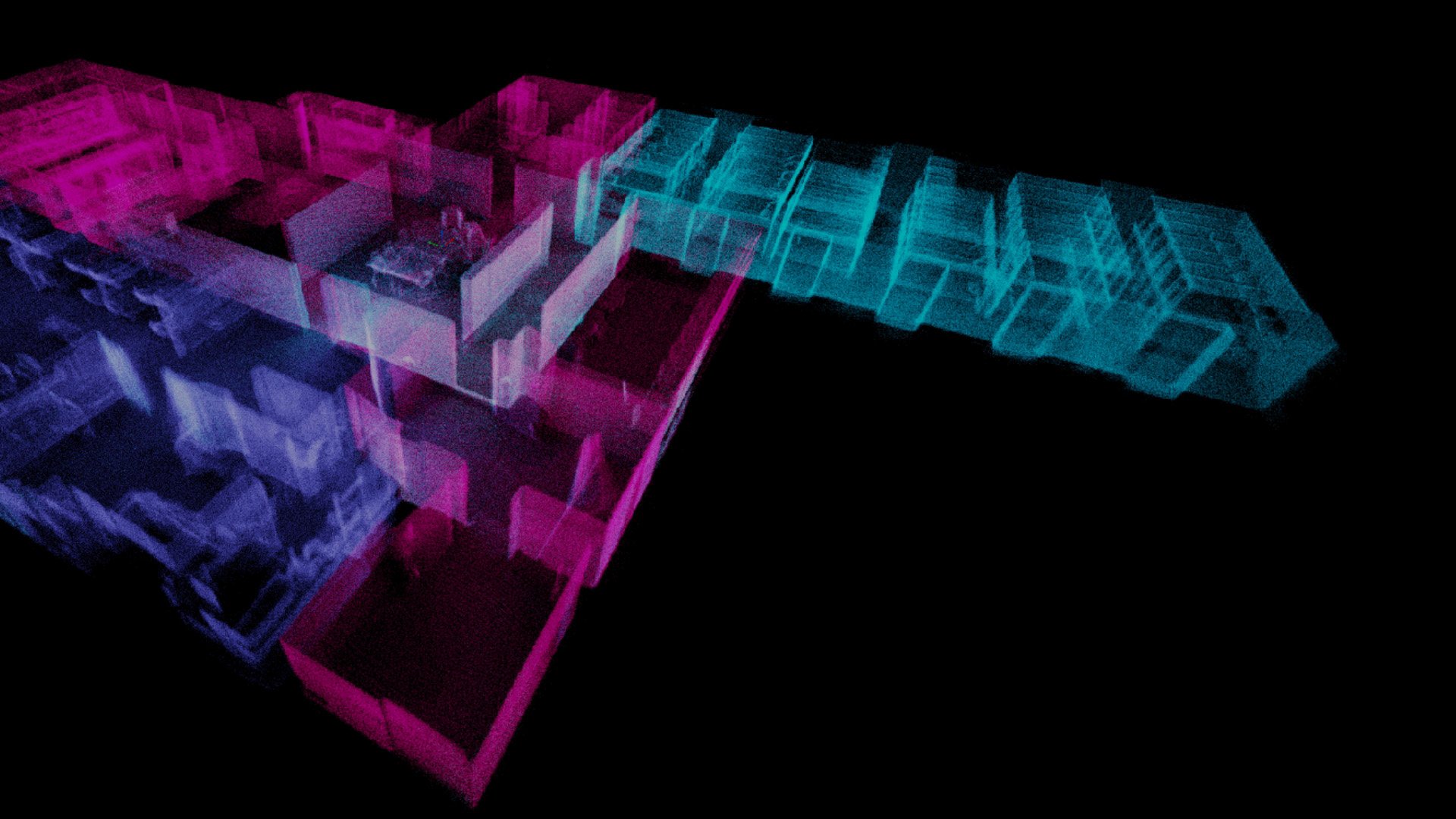

An example point cloud with the Elios 3 UT payload with spot measurements located in the point cloud

The C-bird team then compiled the data into the format required by the class society and submitted the inspection for review. This was significantly quicker than traditional methods as all the data collection was completed in one go, rather than having to move around scaffolding/adjust a mobile elevation work platform (MEWP).

Certified Results From Using The Elios 3 For A UT Ship Inspection

Following a 2-year program of successful pilot projects, C-Bird and the results they produced with the Elios 3 and UT payload were certified by the American Bureau of Shipping, one of the major class societies in the world, as an approved recognized service supplier for ESP hull gauging (Enhanced Survey Program). This recognition was the first of its kind, highlighting the value of C-Bird’s achievements with this type of drone inspection.

Watch the Elios 3 use its live 3D model to guide the drone and make a UT measurement, marking it as a point of interest for ease of reporting.

The Elios 3 provided C-Bird with 5 key benefits. Firstly, the C-Bird team could easily localize the UT spot measurements within a clear point cloud. Secondly, the inspector was able to access the entirety of the space more easily than with scaffolding or alternative methods, while still ensuring his safety and cutting any risk exposure. Next, the drone provided reliable results that were certified by the class inspector. Fourthly, the versatility of the Elios 3 provides it to be a comprehensive inspection tool that can be used in a variety of environments with relevant payloads according to the project. In the end, C-Bird was able to provide detailed results to the client with a clear report that matched the required format for the class society. This was critical to proving the value of the drone as not only a UT inspection tool but an asset that can be rolled out for multiple ship inspections.

C-Bird will continue to use the Elios 3 and UT payload to complete visual and ultrasonic thickness inspections on assets across multiple industries, from maritime to oil and gas to asset management. The comprehensive results achieved with the drone set the company apart from competitors and traditional methods through the heightened speed, safety, and comprehensive data quality they achieved. This method has unlocked a new era for confined space and challenging UT inspections - and C-Bird can’t wait to deploy the Elios 3 in new and exciting projects.

Discover more about the Elios 3 and its UT payload

.png)

.jpg)

.jpg)