Why invest in cement plant drone inspections?

Many inspections in cement plants require scaffolding and/or people to enter confined spaces. This is most common for silo, kiln, or cyclone inspections. The Elios 3 drone was built to avoid putting humans in these dangerous situations and provide an alternative way to inspect high and confined spaces. With cement plant inspection drones, you eliminate the need for scaffolding and get real-time data on the condition of an asset on demand. This empowers significant cuts to asset downtime (95% or more on a cyclone inspection) and inspection costs (spend only $4k for a whole silo inspection).

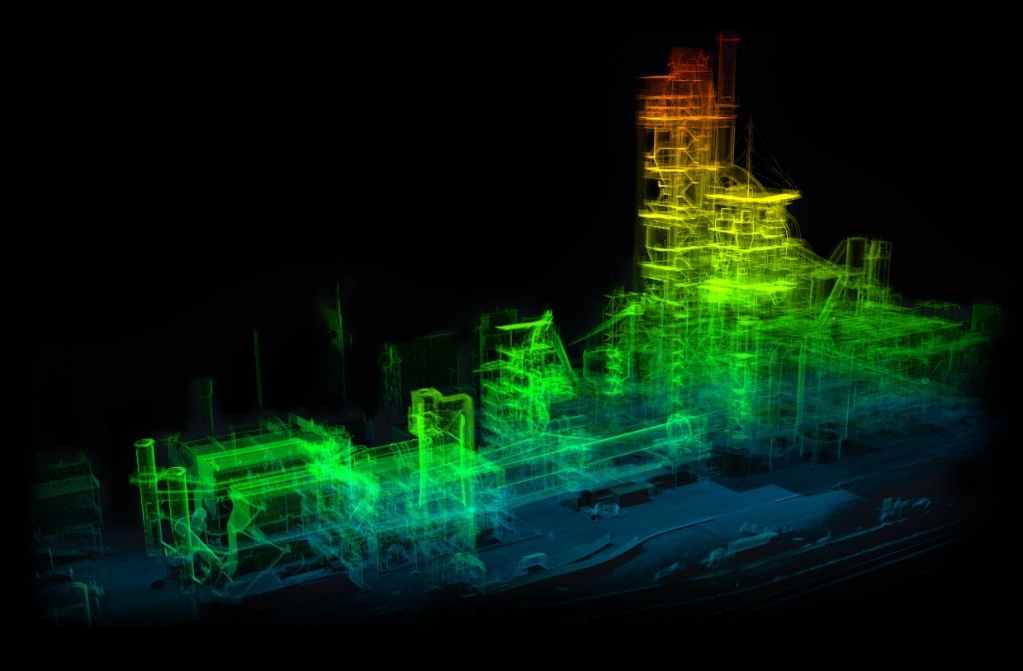

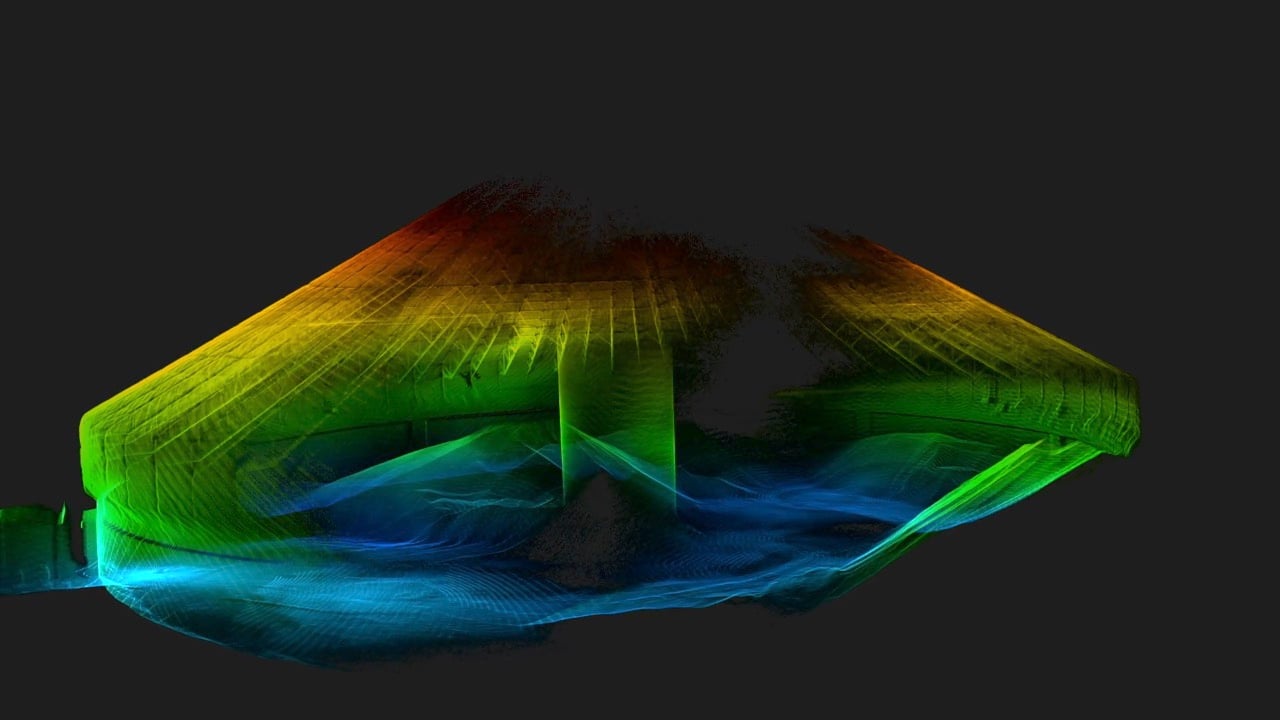

A cement plant drone doesn’t just provide a visual inspection. Take advantage of Flyability’s

UT payload for accurate ultrasonic thickness measurements and Surveying Payload for precise 3D modeling, digital twinning, and volume calculations.

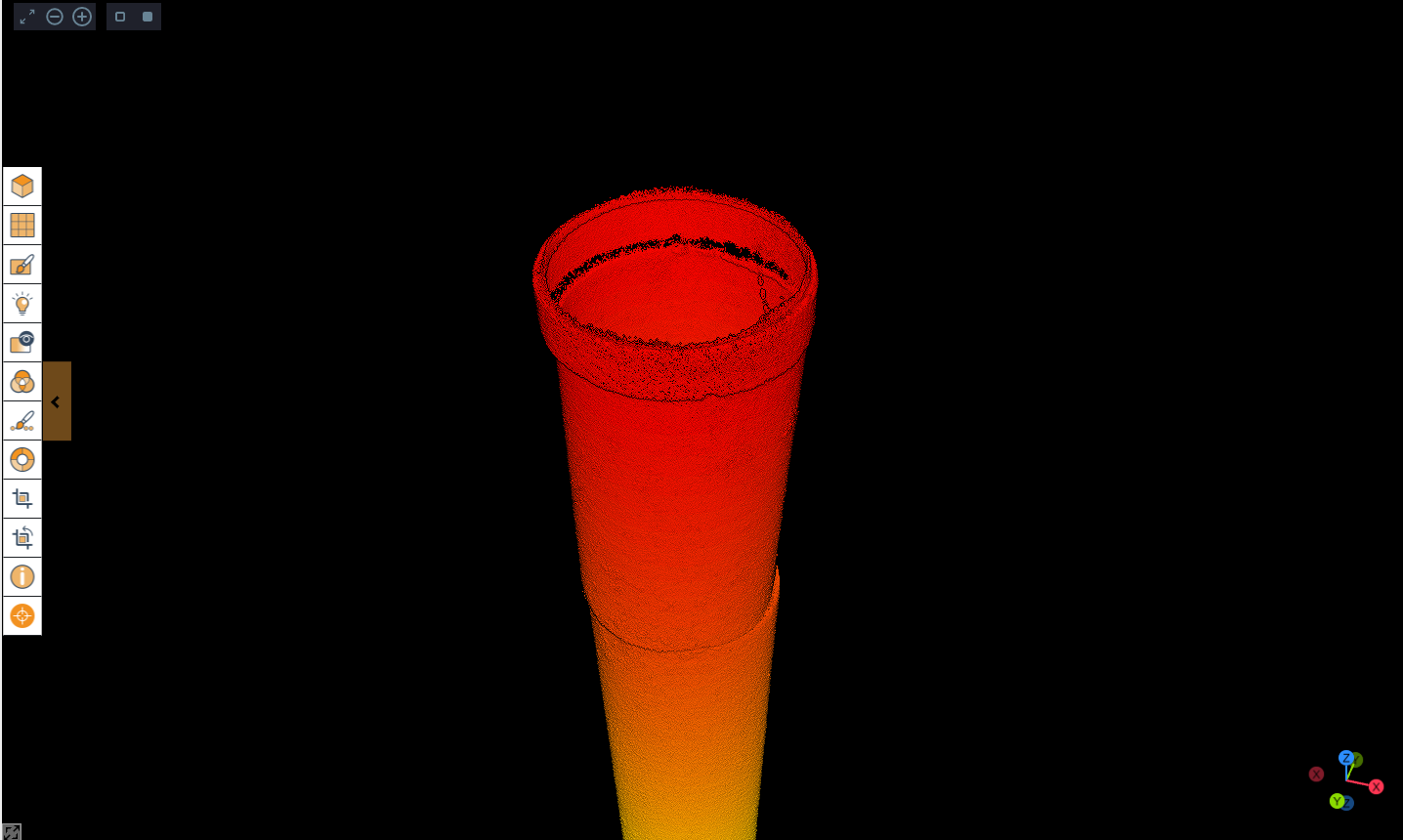

Image represents: Software output and 3D model captured by the Elios 3 while performing a digital twin of a cement plant.

The benefits of adopting cement plant inspection drones

Eliminate Risks

Avoid personnel working at height and send robots instead of humans into hazardous, confined spaces such as silos, kilns, or cyclones.

Reduce Costs

Reduce inspection downtime and costs by up to 95% by eliminating scaffolding or rope access and cutting preparation time, post-work clean-up, and confined space entry procedures.

Enhance Efficiency

Increase the frequency of inspections & improve predictability for tasks related to shutdown planning.

Proven applications for cement plant inspection drones

Succeed at performing complex missions - no matter the conditions

-

Cyclone inspection

Read moreIn just 4 hours, assess the general condition of a cyclone and take note of wear areas, damages, indications of loose material, and air leaks. Thanks to the 3D Live Map, ensure you get full coverage inside the asset with no need for human entry and reduce inspection costs by +90% compared to traditional methods (from eliminating scaffolding).

-

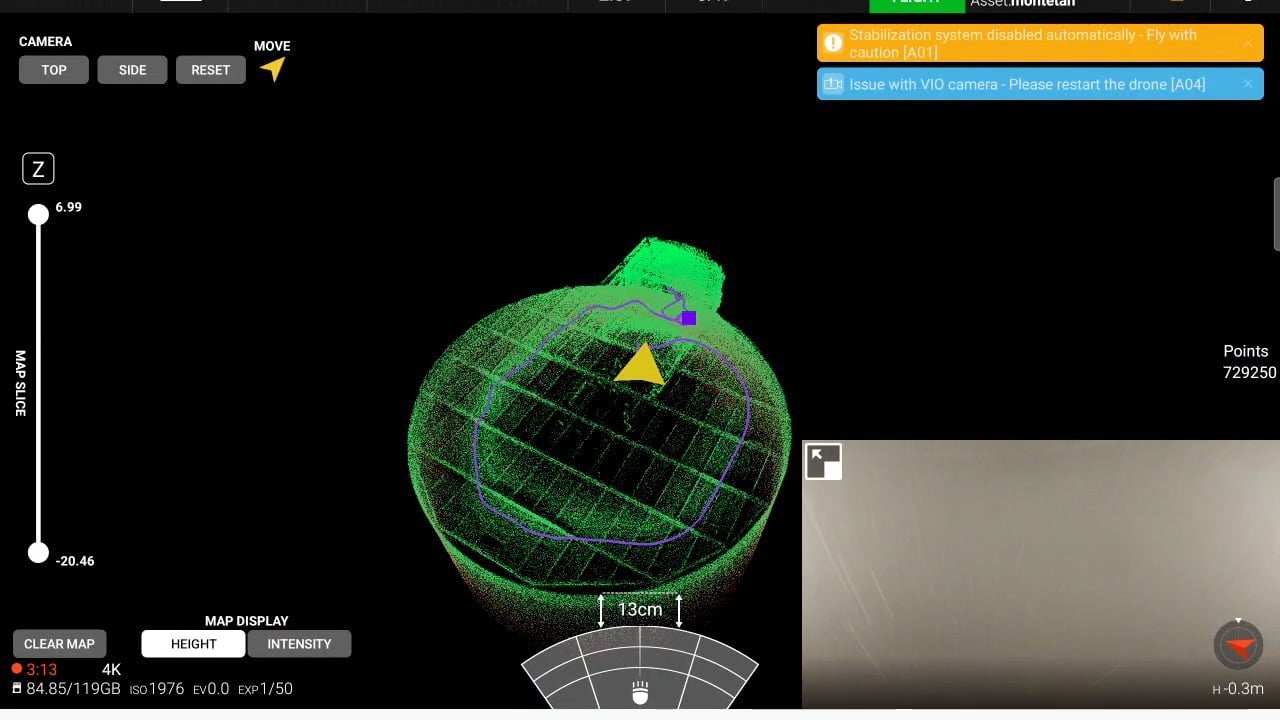

Silo inspection

Read moreBenefit from +80% cost reduction (from reducing downtime) Perform roby performing routine silo inspections to spot potential structural issues and plan for appropriate maintenance. Use a drone to examine common areas of silos failure like foundations, walls, and roofs and inspect a whole silo in just 15 minutes with no human entry required.

-

Stack inspection

Read moreQuickly identify cracks, missing bricks, and other defects on the inside of a 50-meter high chimney. Use 3D LiDAR data to precisely locate anomalies and monitor their evolution over time in less than 1 hour and reduce inspection costs by +90% compared to traditional methods by eliminating the need for 4 rope access specialists working over 2 days.

-

Kiln inspection

Read moreUse a drone to carry out in-house inspections inside the kiln before sending in humans. Precisely detect and locate cracks on the refractory and quickly plan maintenance allowing you to proceed with small repairs before issues get bigger.

-

Stockpile volumetry

Read moreUse the Elios 3’s LiDAR data to map indoor stockpiles in just one flight, ensuring efficient and compliant stock management - even in the biggest silos. By using a drone you will not require any work at height and can collect highly accurate volume measurements in just 9 minutes.

-

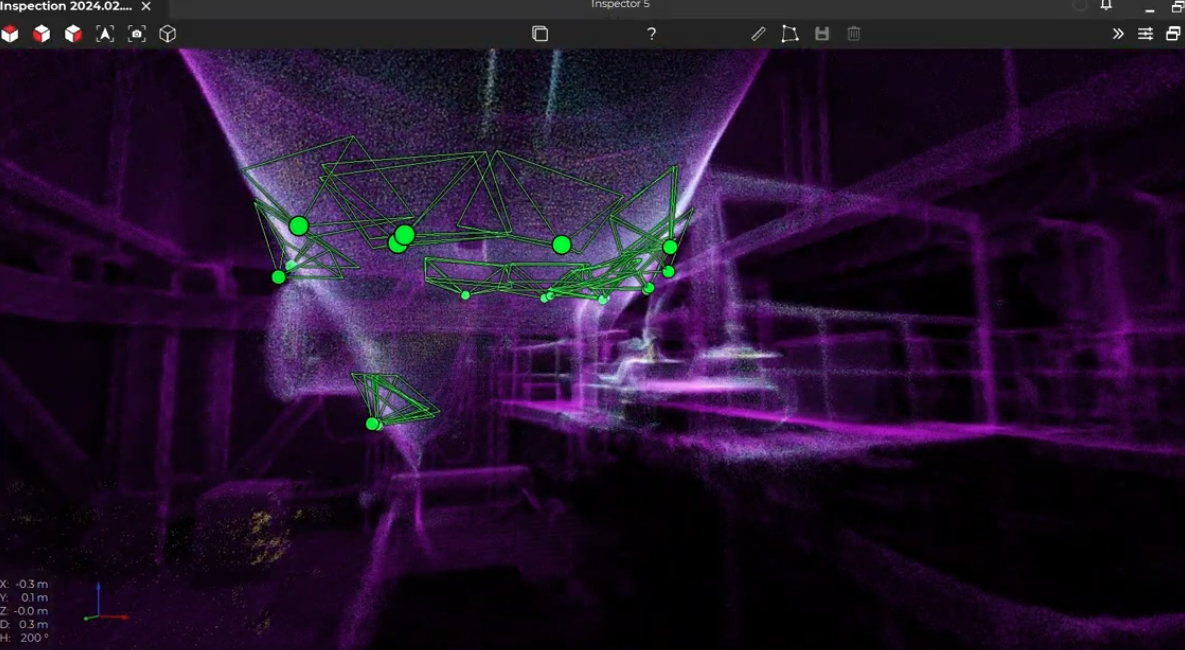

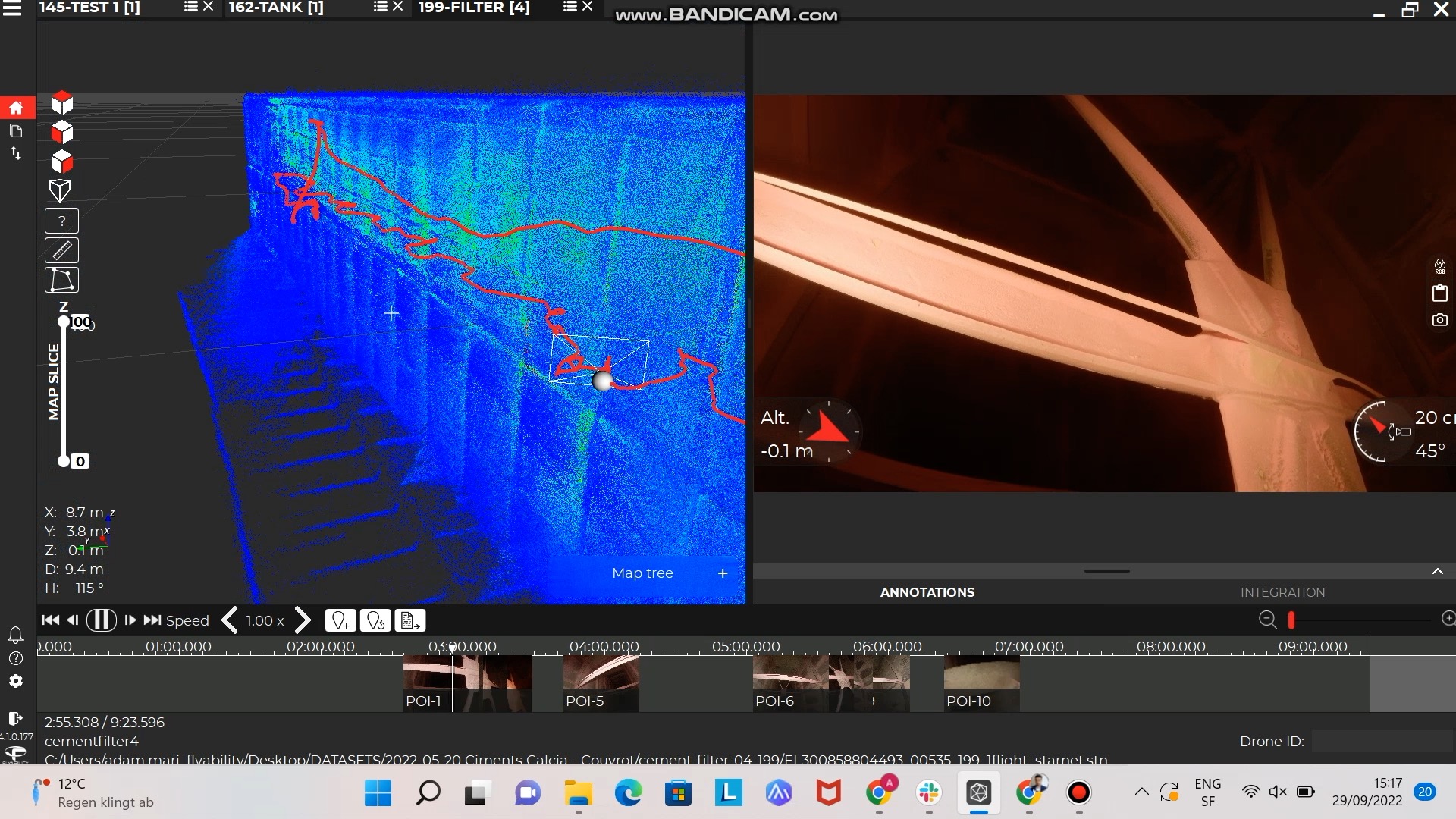

Shaft inspection and software output

Read moreQuickly deploy a drone inside a cement filter to locate defects and rapidly plan for repairs with no human confined space entry. Once a mission is complete (in just 9 minutes), import the data collected into Inspector 5, our companion software, and start analyzing your flight - frame by frame. This will slash asset downtime to just 2 hours compared to 2 days using traditional inspection methods.

-

Digitalize an entire cement plant

Read moreWhat would normally take several days can be done in just a few hours thanks to the power of the Elios 3 Surveying Payload. In just a few hours you can precisely digitalize a whole cement plant in order to update the digital record, help plan maintenance, and locate the areas for installing new assets or carbon capture technologies.

-

Cooling tower inspection

Read moreWithout the need for human entry, a drone can help identify potential climbing hazards, find structural damage, and help inspectors understand the tools they need prior to climbing a cooling tower. Once this information has been gathered, the inspector can follow up and address any issues revealed by the data. All you need is 4 hours for a complete visual inspection of two cooling towers.

See how Elios 3 UT helps our clients save time, money, and stay safe

![]()

“

“Flyability’s drone technology is critical for us because it’s able to be operated in extreme conditions, such as high dust atmospheres. This allows us to perform inspections in difficult-to-access places without exposing our personnel to a risk."

Nazareth Cuevas Divas

Capex Manager US Manufacturing Support at LaFargeHolcim

They already use our products